MEASUREMENT & VERIFICATION (PM&VL 6)

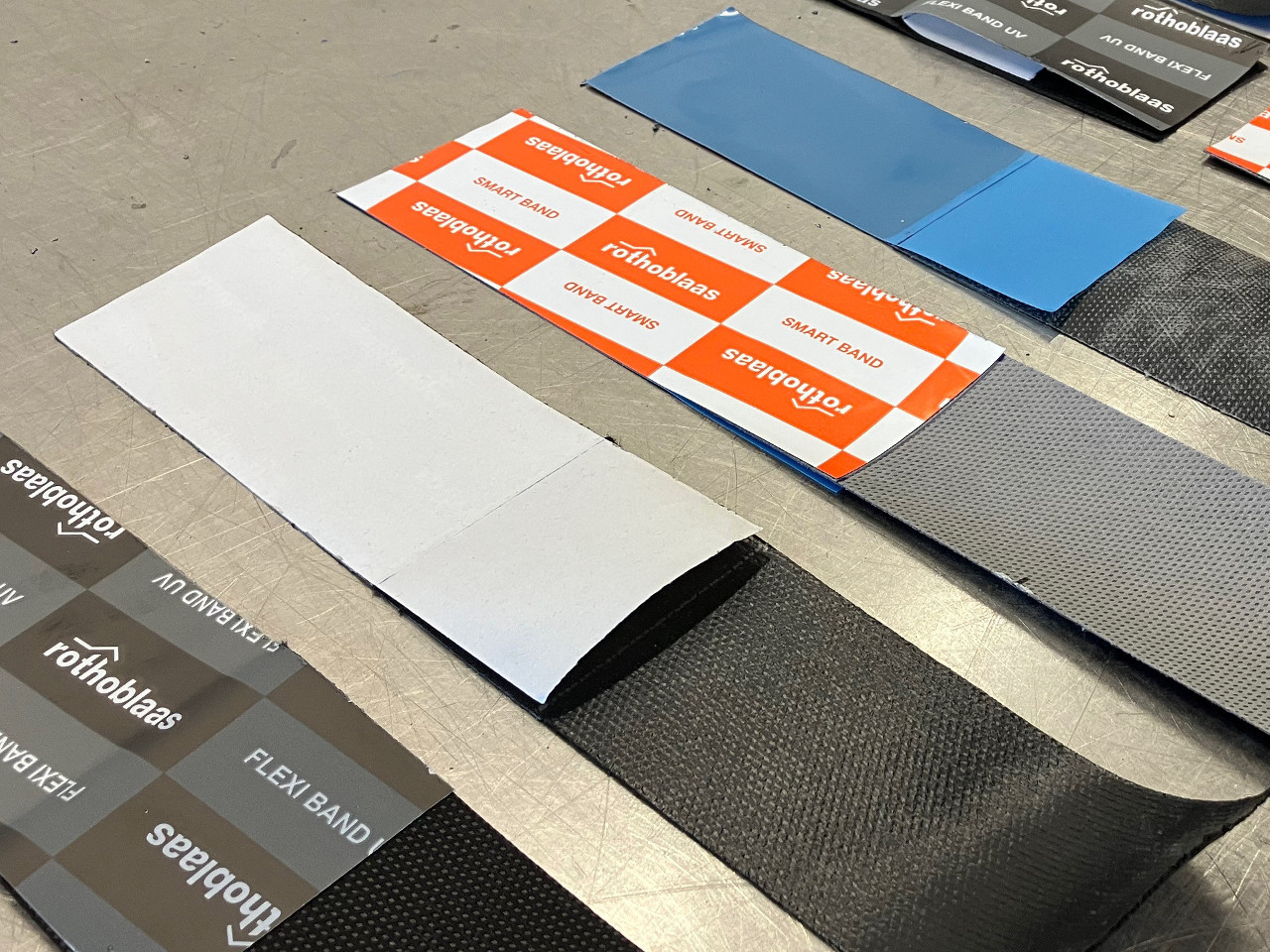

Tested Products:

FLEXI BAND UV tape

TRASPIR EVO UV 115 membrane

and SMART BAND tape

TRASPIR EVO 160 membrane

The tapes are universal single-side adhesive and the membranes are highly breathable monolithic.

ABOUT

Safety

Health

Efficiency

PARTNERS

Scientific partner

Politecnico di Milano (POLIMI)

Industrial Partner

Rothoblaas

Main author:

Sara Bascì

Politecnico di Milano

DETAILED INFO

Click here to download!

The mechanical characterization of different types of products to compare their properties and characteristics and evaluate the possible influence of different external conditioning on the mechanical properties of the elements.

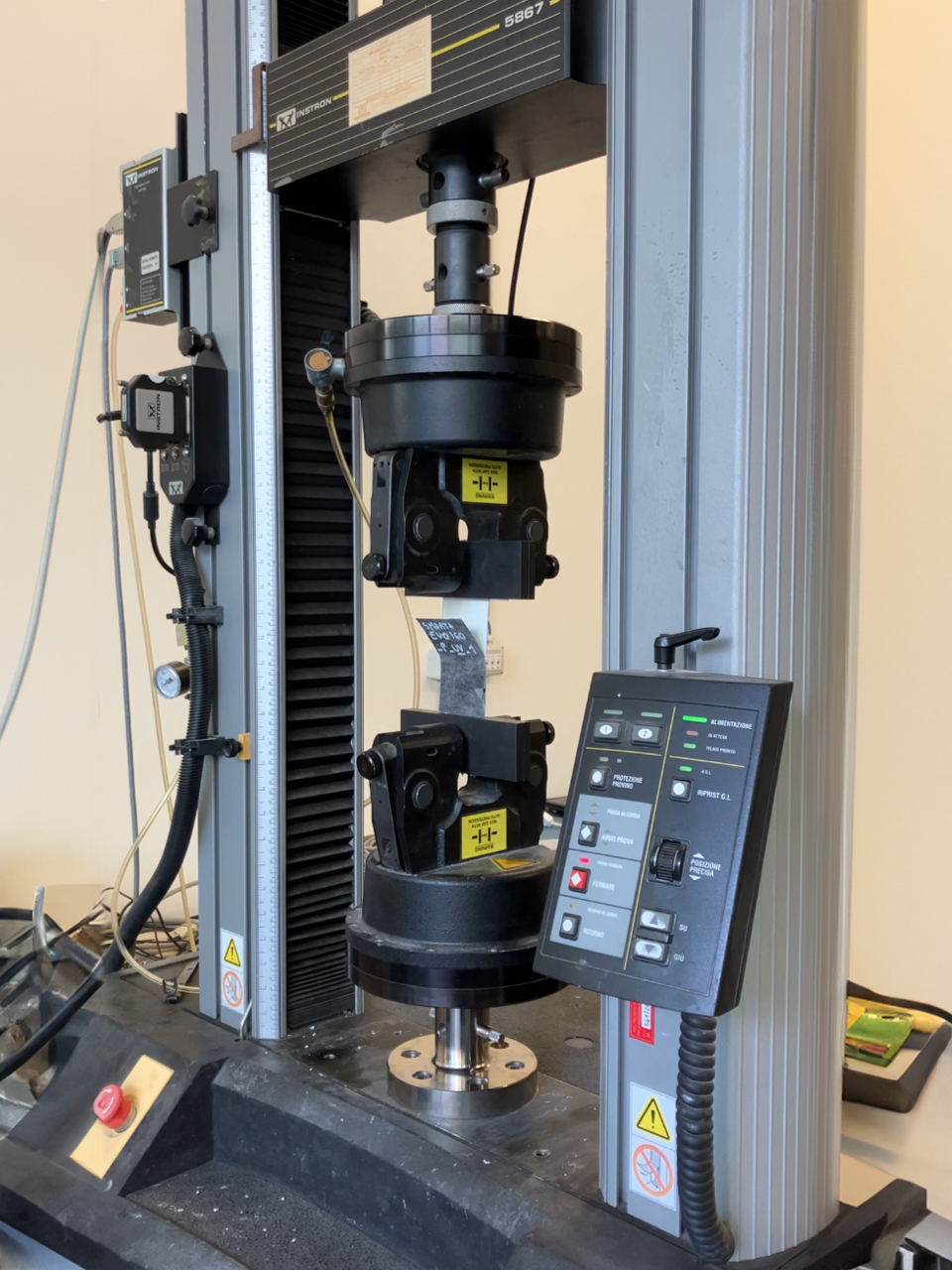

Preparation and testing of tape-membrane joints at M&S Lab

Design of Experiments

Shear resistance of joints

The samples were clamped in an electromechanical press and a tensile force, sufficient to cause the failure or the separation of the joints, was applied vertically to pull the samples in shear. The shear resistance of joint was determined (EN 12317-1:2010).

Peel resistance of joints

The samples were clamped in an electromechanical press and a tensile force, sufficient to cause the failure or the separation of the joints, was applied vertically. The resistance to peeling of joints was determined (EN 12316-1:2000).

The tests were performed after standard conditioning, after one year of UV exposure and after freeze and thaw cycles.

Results

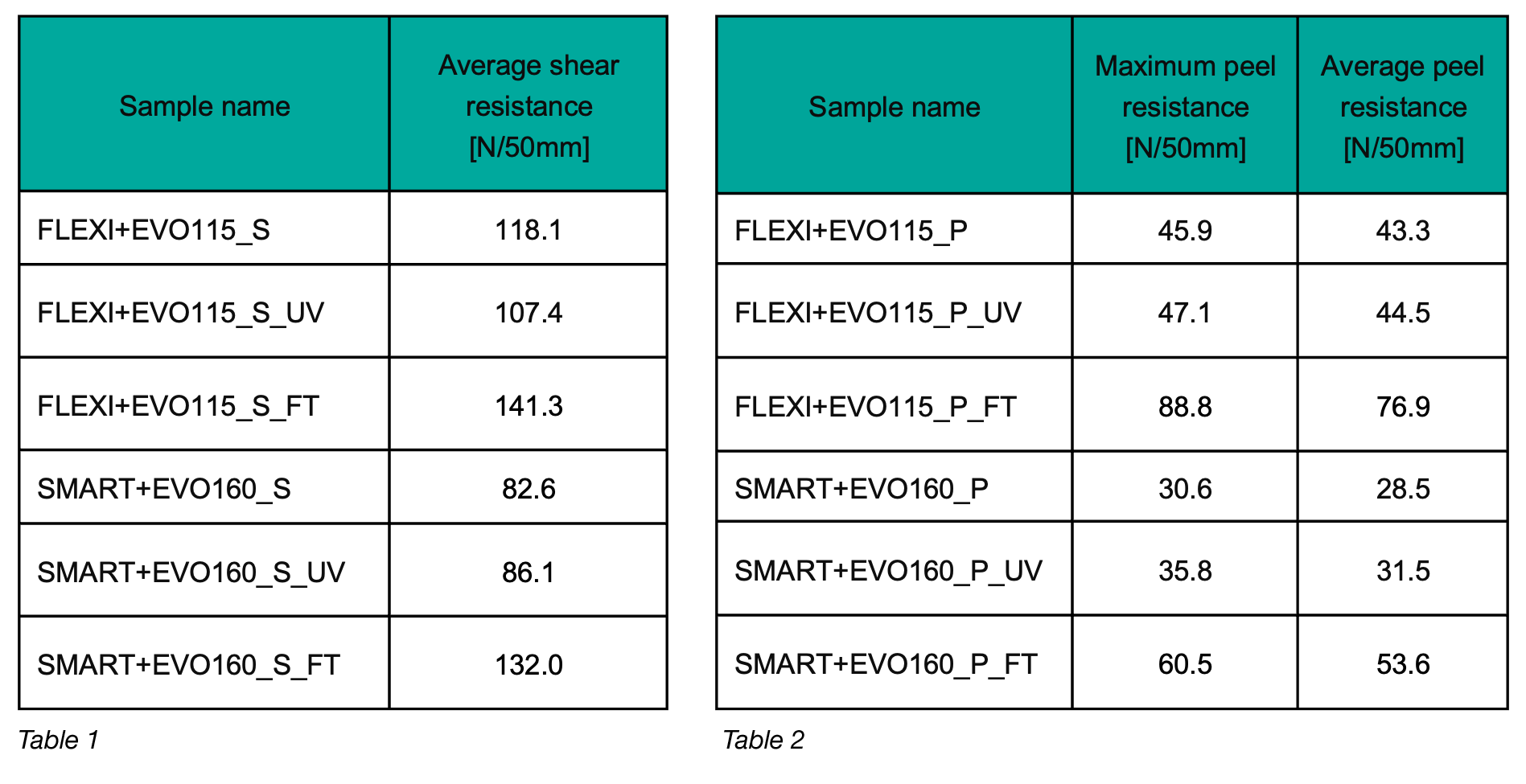

Shear resistance of joints - Table 1

summarizes the average values of the shear resistance of joint, expressed in N/50mm. The repeatability of tests for each type of sample was equal to three.

Peel resistance of joints - Table 2

summarizes the mean values of the maximum peel resistance and of the average peel resistance, expressed in N/50mm. The repeatability of tests for each type of sample was equal to three.

The sample name is composed of a first part that represents the abbreviation of the product name and ‘S’ or ‘P’ which represents the type of test (shear resistance or peel resistance of joints). If there is no additional letters after ‘S’ or ‘P’, it means that the test is performed under normal conditions, otherwise ‘UV’ represents the samples exposed to UV radiation for one year, and ‘FT’ represents the samples subjected to freeze-thaw cycles.

Conclusion

It was possible to mechanically characterize the component, specifically defining the shear and the peel resistance of the joint. It is also possible to compare the various types of specimens by evaluating the influence that different conditionings have on the mechanical properties of the component.