Mechanical, Durability, Acoustic tests and Thermal simulations of window frame

- Home

- Success Stories

- Mechanical, Durability, Acoustic tests and Thermal simulations of window frame

Product: KLIMA-PUR window frame

INDRESMAT is a company founded in 2017 and located in Barcelona (Spain) & Geleen (The Netherlands) that is redefining the thermal envelope of buildings with materials such as biobased Polyurethane window frames and insulation foam.

Mechanical, durability, vibroacoustic, thermal, and microclimate comfort tests of envelope products and their connectors. Mechanical, vibroacoustic, thermal, and structural (scanning and optical microscope, spectrometer) tests are used for ageing diagnosis.

Main author:

Aneta Nowak-Michta

Cracow University of Technology

Low temperature cracking according to EN 12697-46 with modifications.

Durability:

- Resistance to artificial ageing by exposure to freeze-thaw according to EN 13165 with modification.

- Resistance to accelerated ageing by exposure to temperature in accordance with the requirements of EN 13165.

Diagnostics of durability due to ageing included features not defined in the standard: Mechanical test before and after artificial ageing - Strength of corners according to EN 514.

Direction-averaged junction velocity level difference for connector or for connection model according to our own procedure based on EN ISO 12354-1 and EN ISO 12354-2.

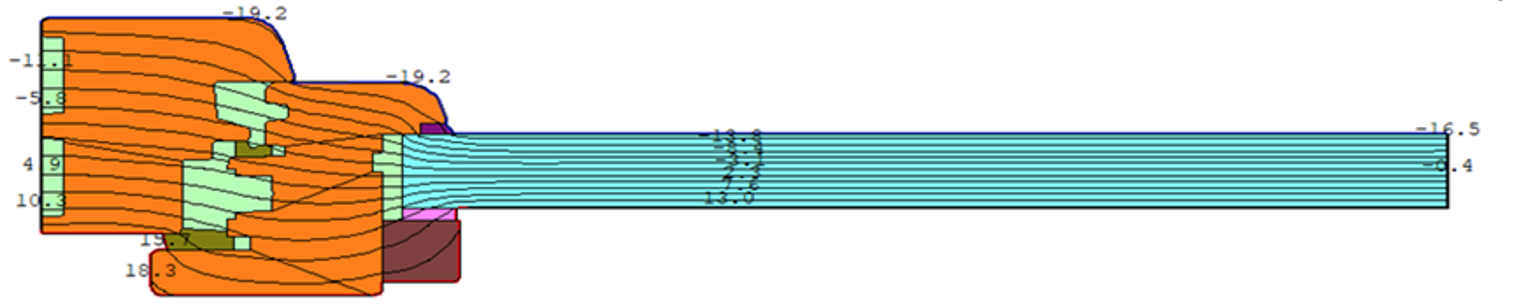

Internal surface temperature according to EN ISO 13788.

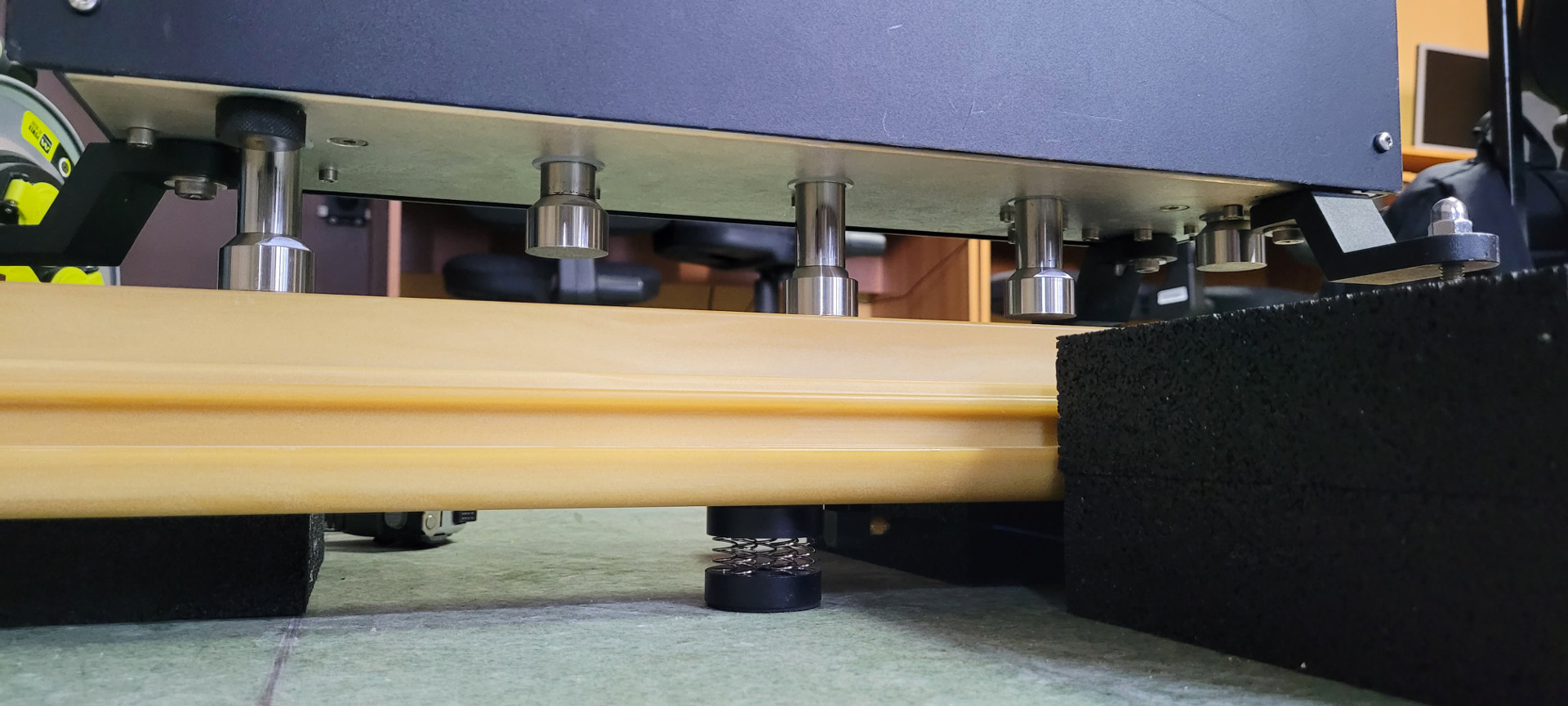

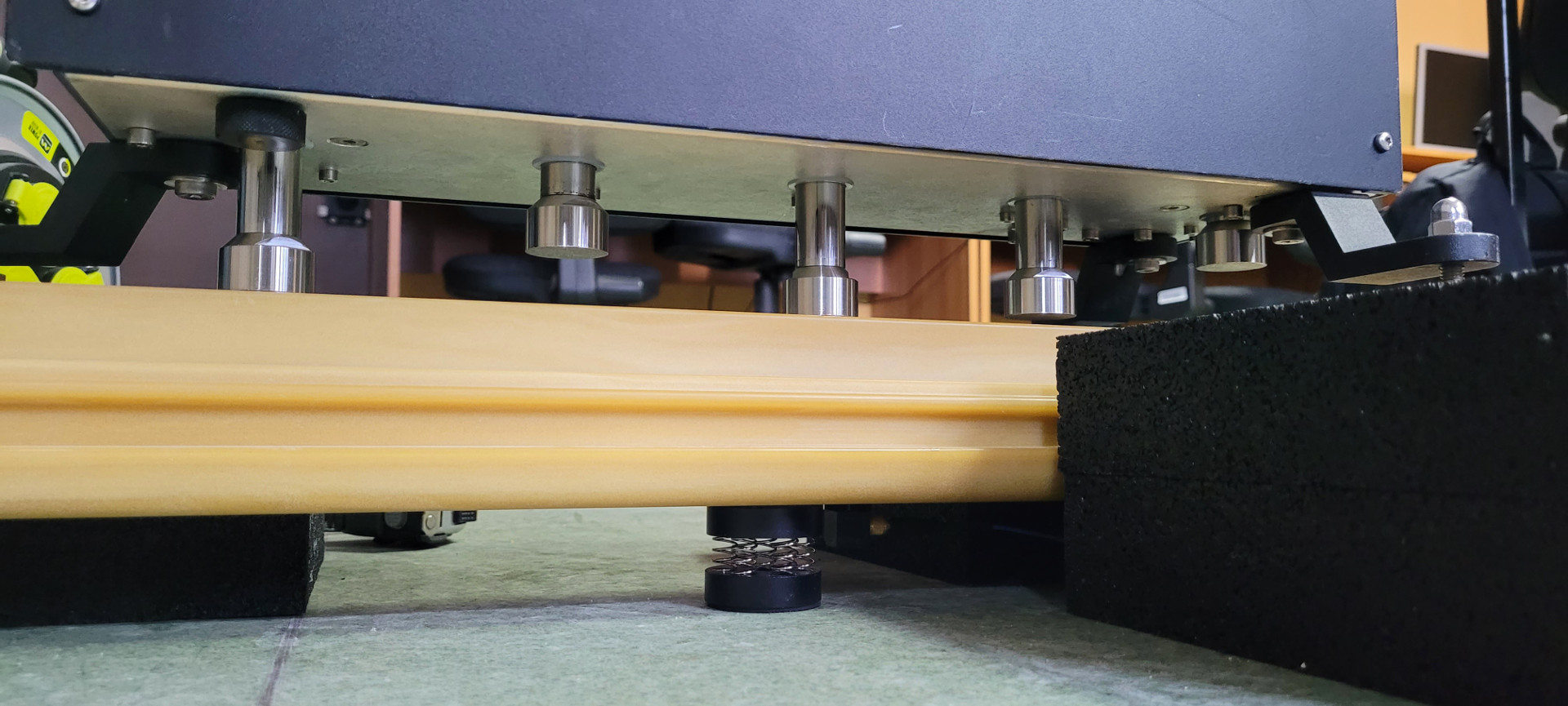

Top: Strength of corner

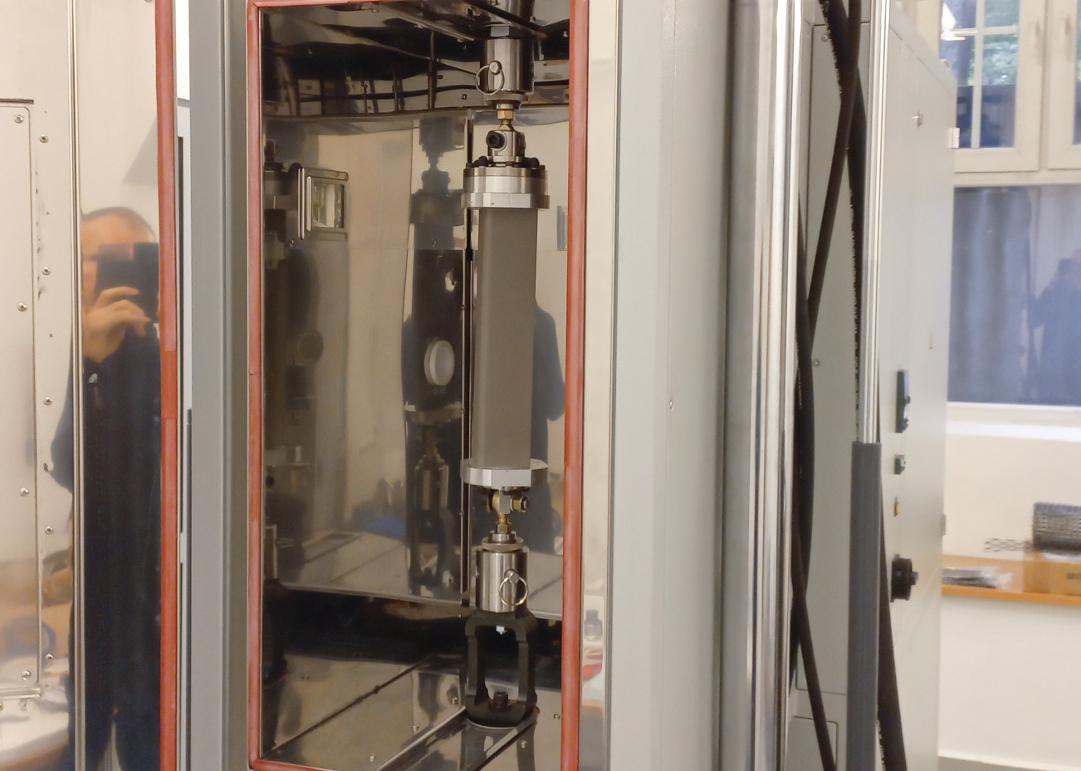

Middle: Low temperature cracking

Bottom: Velocity level difference

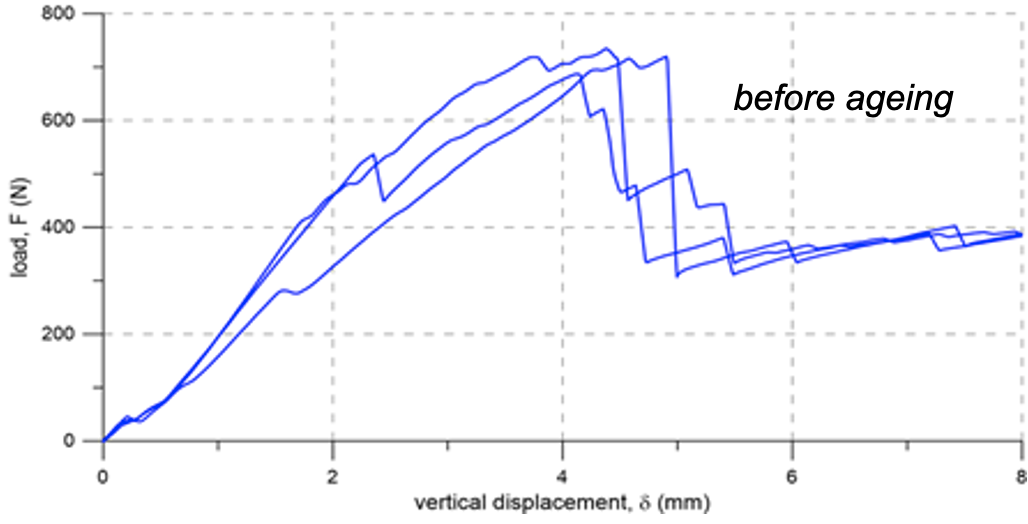

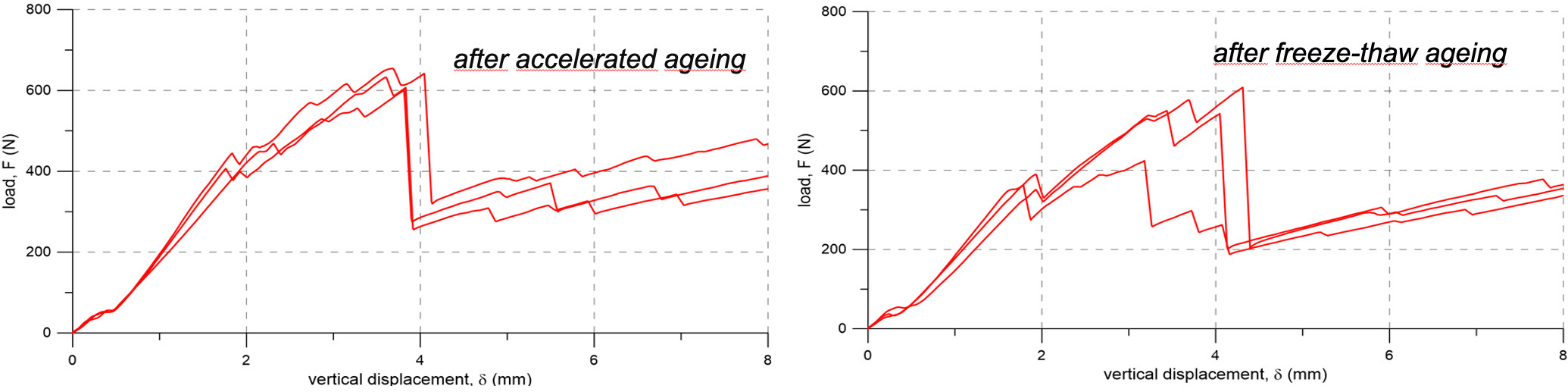

Strength of the tested window frame corners is 3.3 N/mm2, 2.5 N/mm2 and 2.9 N/mm2 for reference specimens, specimens after freeze-thaw ageing and specimens after accelerated ageing, respectively. Relationships between load and vertical displacement of corners before and after ageing.

In the low temperature cracking test, the average value of maximum cryogenic stress was equal to 1.36 MPa.

Foamed (bio)polyurethane frame connections found to be acoustically stiff. Average transmission of vibration velocity in frequency domain is below 6 dB.

Relationships between load and vertical displacement of corners:

The purpose of the test was to check whether condensation and mold may occur on the inner surface of the window frame. The temperature distribution in the edge and middle element of the window frame was calculated as a 2D task. As a result of the analysis, it was found that in typical residential and office spaces with a moderate level of relative air humidity, condensation of water vapor will not occur. However, an influence of the applied specific glazing should also be checked

The temperature distribution in the edge of the window frame:

Both types of the used ageing procedure caused reduction in strength of the tested window frame corners.

In the low temperature cracking test, the specimens met the required evaluation criterion.

Biopolyurethane frame connections found to be acoustically stiff.

Mechanical and Durability

30 July, 2023