Flexible structural connectors

- Home

- Success Stories

- Flexible structural connectors

FlexAndRobust line of products is developed from polyurethane flexible joints which are dedicated to structural and non-structural bonding of elements made of various materials (concrete, masonry, timber or steel).

The PM&VL9 is built on a deep understanding of the performance of wood-based envelope elements and structures. It focuses on specific issues, properties, and performances of wooden structures, addressing essential requirements — from fire reaction to sustainability, including environmental footprint considerations.

Main author:

Dr. Urška Blumauer

ZAG Institute

1- Cone calorimeter test according to ISO 5660-1.

2- Small flame test according to SIST EN ISO 11925-2.

3- Fire resistance test of joints with furnace conditions and temperature measuring method according to SIST EN 1363-1.

Tested specimens:

PST_I (top) and PM_P (bottom) type of flexible structural joint by FlexAndRobust.

Cone calorimeter tests: Flexible joint between two timber members was tested with constant incident heat flux of 50 kW/m2. Three conditions have been considered; with joint in line with structural surface, and with joint 20 mm and 40 mm withdrawn from the surface to simulate reduction of the material inside the joint. In the first case the joint material ignited before the surrounding wood, otherwise it ignites when the wood burning front reached the joint surface.

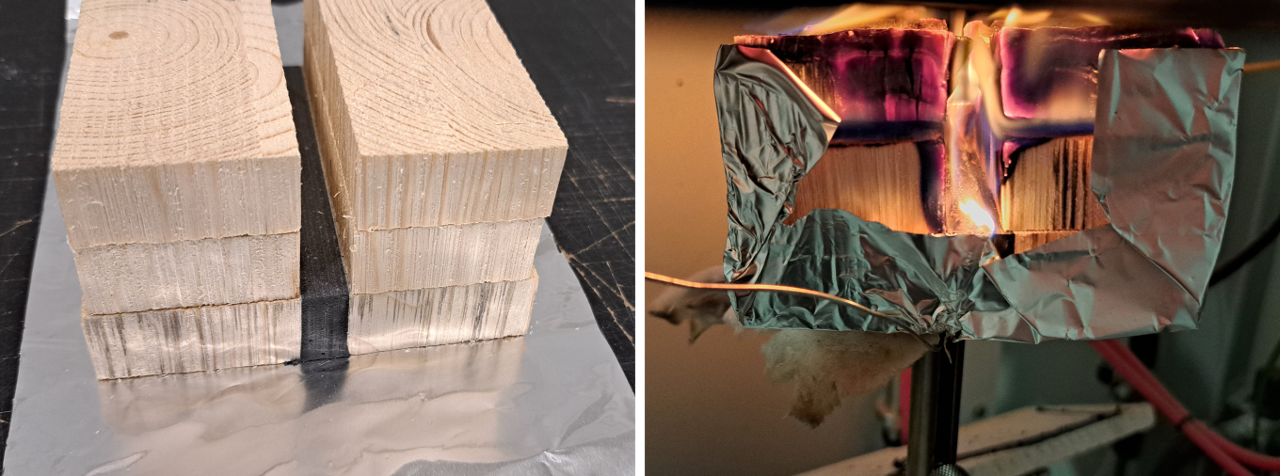

Cone calorimeter test of flexible joint – simulation of reduction of material.

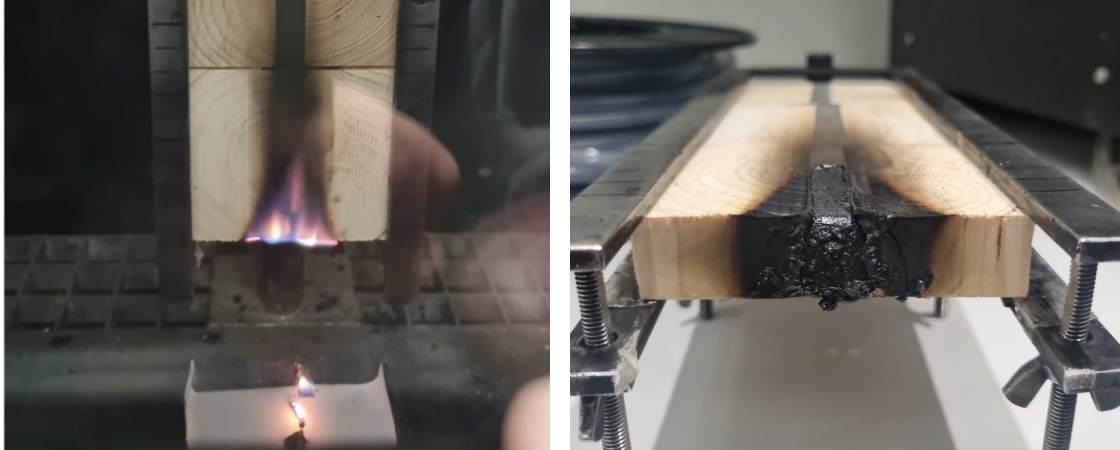

Small flame test: Flexible joint was exposed to a small flame for 30 seconds at the edge and the surface of the joint. Flexible joint material PST_I and PM_P ignited and in case of PM_P flaming droplets ignited filter paper under the test specimen as well. Flaming of the material did not stop after the pilot flame removal.

Small flame edge exposure for 30 s results in ignition of the flexible joint and dropping of flaming material.

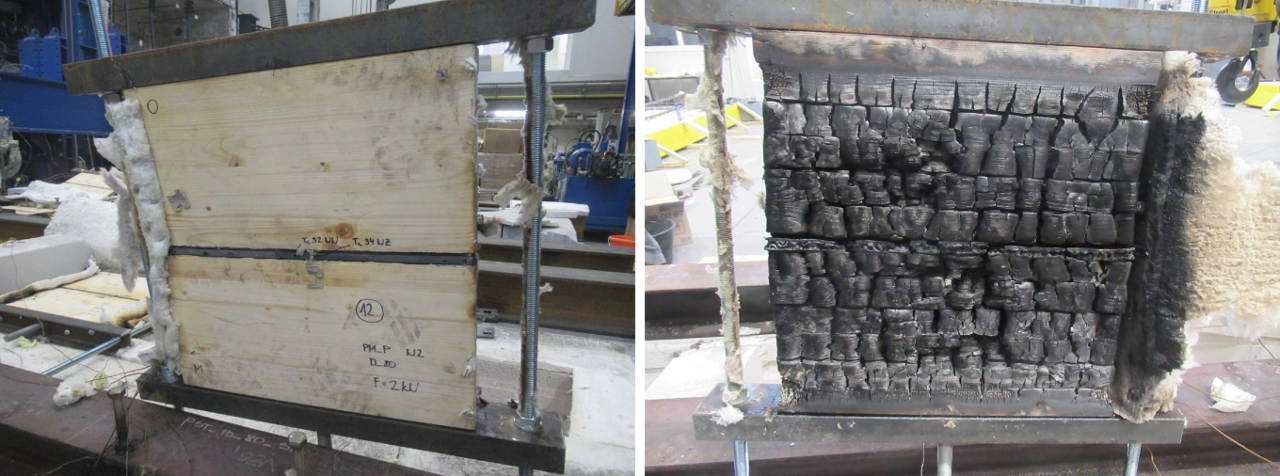

Fire resistance test: Flexible joint was exposed to a small flame for 30 seconds at the edge and the surface of the joint. Flexible joint material PST_I and PM_P ignited and in case of PM_P flaming droplets ignited filter paper under the test specimen as well. Flaming of the material did not stop after the pilot flame removal.

Flexible joint in tension after fire resistance test: unexposed side (left), exposed side (right).

Cone calorimeter tests indicated that when polyurethane material is exposed to direct heat flux, it ignites before the surrounding timber. The small flame test show that polyurethane material did not stop burning after the pilot flame was removed. In the fire resistance test it was noticed that timber specimens (with one or two polyurethan joints) in case of collapse, collapsed through timber. The results are of research interest and show that timber elements of stronger mechanical properties should be used to obtain collapse through the flexible joints in case of fire resistance test.

The research activity was conducted exclusively between ZAG and FlexAndRobust. Fire resistance test design was custom made for this specific product since it is a mix of sealant and kit material. The results will be shared in a scientific paper that will be jointly written by both partners.

Fire resistance

06 October, 2025