Testing nanoparticle-based coatings hygrothermal properties

- Home

- Success Stories

- Testing nanoparticle-based coatings hygrothermal properties

Product: Nanoparticle coating

TECNAN was created in December 2007 and offers a wide spectrum of nanoparticle materials, which can be employed as catalysts for the automobile industry and the energetic sector, sensors for gases and atmospheric pollutants, photocatalysts, materials for lighting devices, and many other uses. But also, multifunctional nanoparticle-based coatings addressed for sectors as renewable energies, buildings, medicine, 3D printing, automotive or wood among many others.

The scope of the PM&VL2 is a complete characterization of all the envelope parts and their effects on internal occupants in real operating conditions. An important feature the PM&VL2 will offer is the coupling of testing and modelling activity, hence exploiting the tests in order to calibrate models and broadening the analyses.

Main author:

Marco Larcher

EURAC Research

The tests were carried out according to the following procedures:

The water absorption properties were determined measuring the water uptake coefficient by partial immersion according to the standard EN ISO 15148:2016.

The vapor transmission properties were determined using the cup method according to the standard EN ISO 12572:2016

The substrates where tested both before and after the application of the coatings.

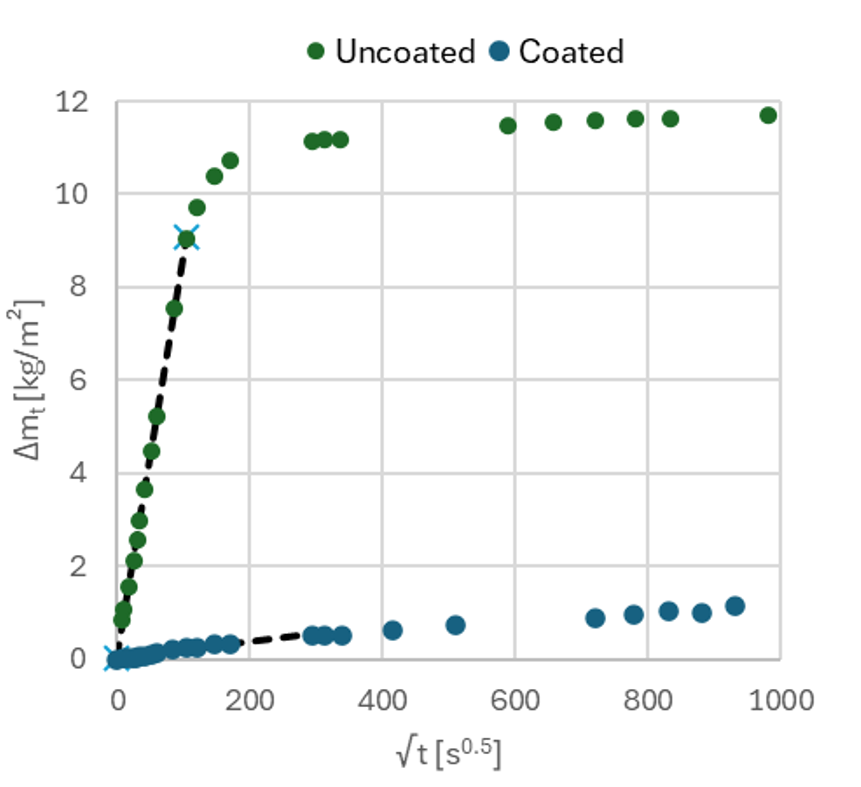

Comparison of the water absorption curve for an uncoated specimen of lime plaster and one treated with COATING B.

COATING B reduces drastically the water absorption coefficient by partial immersion, Aw, for both substrates. The ratio between the average Aw value of the treated samples and the one of the untreated samples is 0.02.

COATING B does not increase the water vapour resistance factor, µ, for both substrates even if with a difference from the quantitative point of view. As regards the stone substrate the ratio between average µ value of the treated samples and the one of the untreated samples is 1.14 (value obtained removing one outlier) while, for plaster, the same ratio is 1.03.

COATING A has a different impact on the two substrates as regards the water uptake coefficient by partial immersion, Aw. For the plaster substrate the observed Aw is on average even higher for the treated samples than the untreated ones. For the stone substrate there is a reduction of Aw and on average the ratio between the treated and the untreated Aw is 0.09.

COATING A has a negligible impact on the vapour diffusion properties of the two substrates. In the case of the stone a slight increase of μ value is observed on average while in the case of the plaster a slight decrease.

Both coatings are addressed to avoid water contact with surface of the substrate. However, they have not been developed to work at immersion conditions, hence the test conditions are representing an extreme exposure for the specimens. However, even under extremely harsh conditions both coatings have revealed good performances on top of two substrates. More in detail, COATING B has proven to be promising for use as a water-repellent coating, as it reduced the water absorption coefficient by approximately 98%, while modifying the vapour resistance factor to a limited extent.

By its part, characterization of COATING A has also exhibited a great vapour transmission; since vapour resistance factor is completely comparable to non-treated samples on both substrates. But also, has shown a significant reduction of the water absorption coefficient in for stone substrate (up to 91%). Meanwhile, due to porosity of the plaster, a further optimization in terms of dosage and application has to be completed to reach previous values.