MEASUREMENT & VERIFICATION (PM&VL 7)

Product: SAFE-PUR sandwich panel

INDRESMAT is a company founded in 2017 and located in Barcelona (Spain) & Geleen (The Netherlands) that is redefining the thermal envelope of buildings with materials such as biobased Polyurethane window frames and insulation foams.

Mechanical, durability, vibroacoustic, thermal, and microclimate comfort tests of envelope products and their connectors. Mechanical, vibroacoustic, thermal, and structural (scanning and optical microscope, spectrometer) tests are used for ageing diagnosis.

ABOUT

Safety

Health

Efficiency

PARTNERS

Scientific partner

Cracow University of Technology

Faculty of Civil Engineering

Industrial Partner

Indresmat

Main author:

Aneta Nowak-Michta

Cracow University of Technology

The completed program of mechanical and durability tests as well as thermal simulations was based on the certification requirements for sandwich panels with appropriate modifications taking into account the biopolyurethane raw material used as the core and the designed solutions for their connections. The obtained results indicate a path for further research and product development and can also be used during product certification.

Design of Experiments

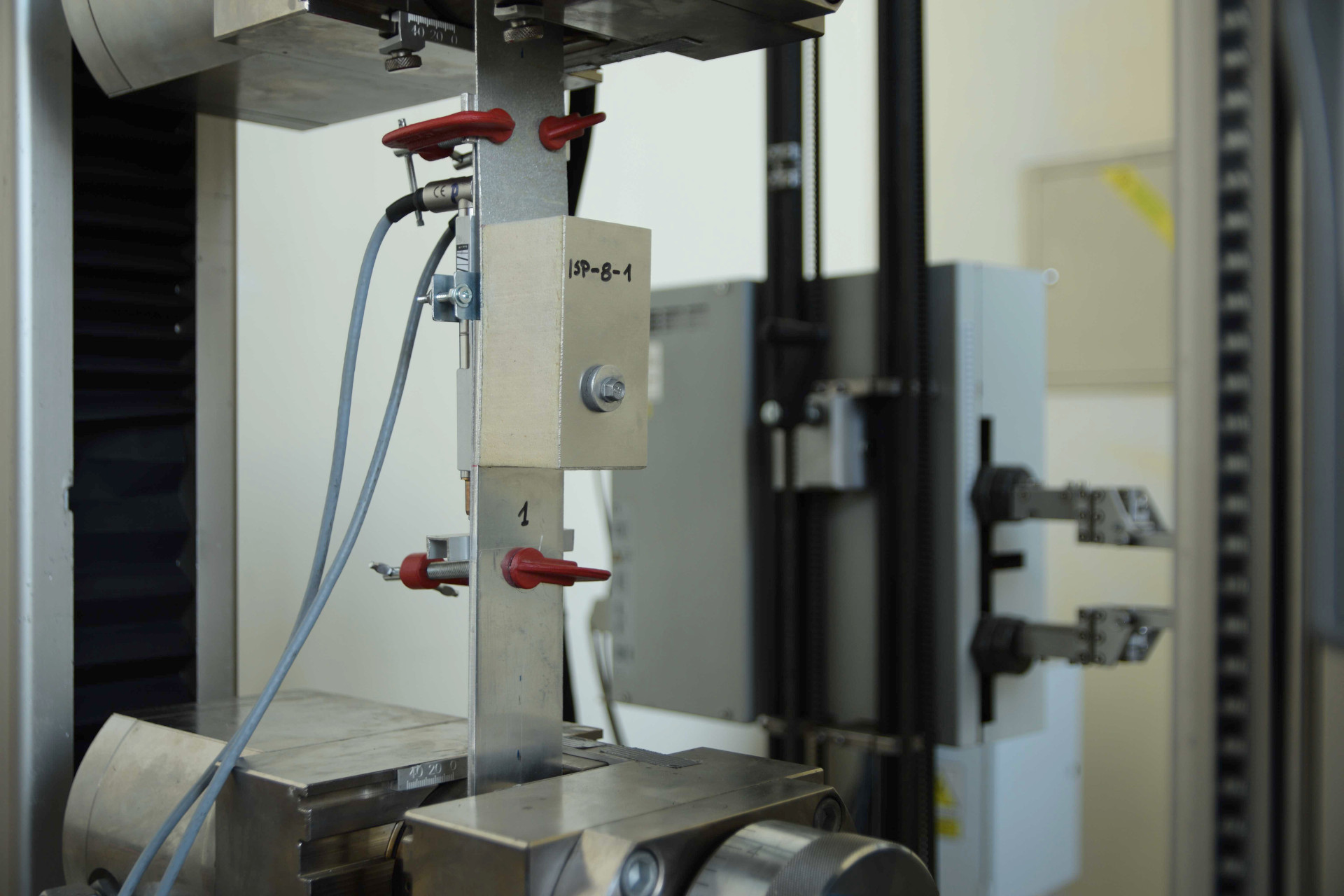

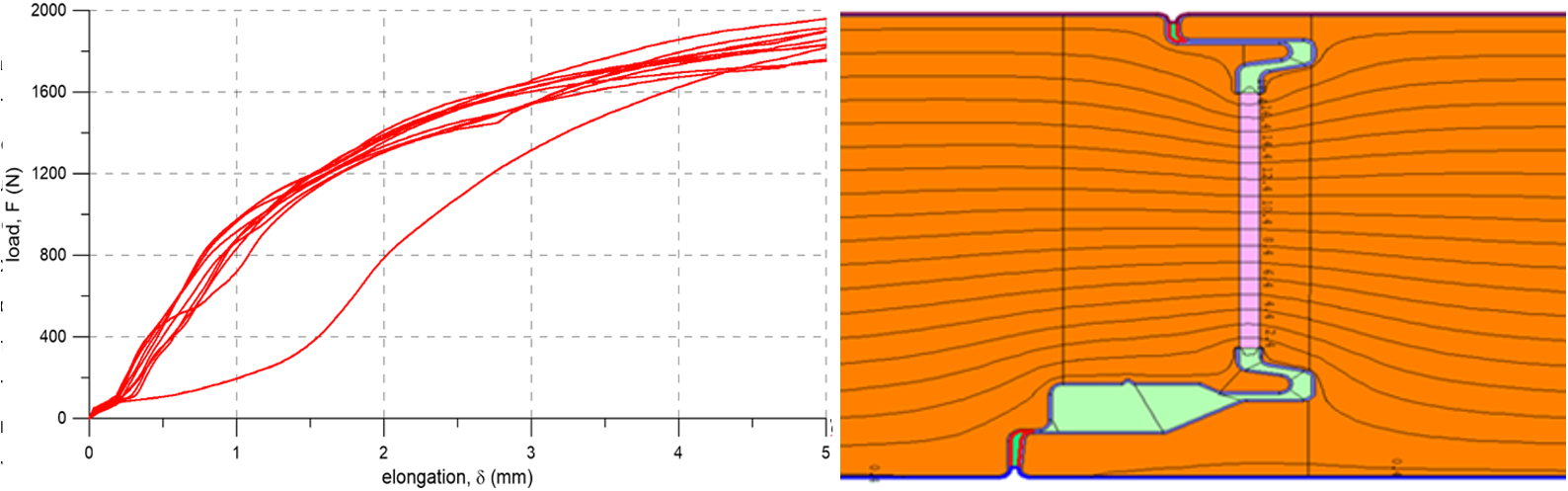

Shear resistance of the connection according to EAD 330047-01-0602.

Durability - Change in thermal conductivity over time as a result of ageing according to Annex B of EN 14509 - DUR 1. Diagnostics of durability due to ageing included features not defined in the standard: Thermal test before and after artificial ageing - Thermal conductivity according to EN 12667 with modification.

Water vapour diffusion (Interstitial water vapor condensation risk and intensity) according to EN ISO 13788.

Internal surface temperature according to EN ISO 13788.

Linear thermal transmittance according to EN ISO 10211.

Results

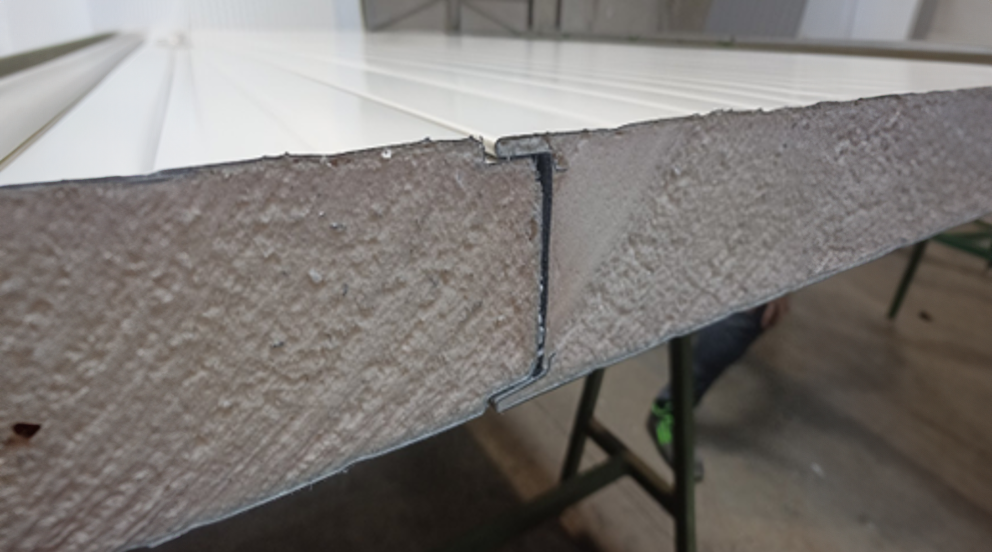

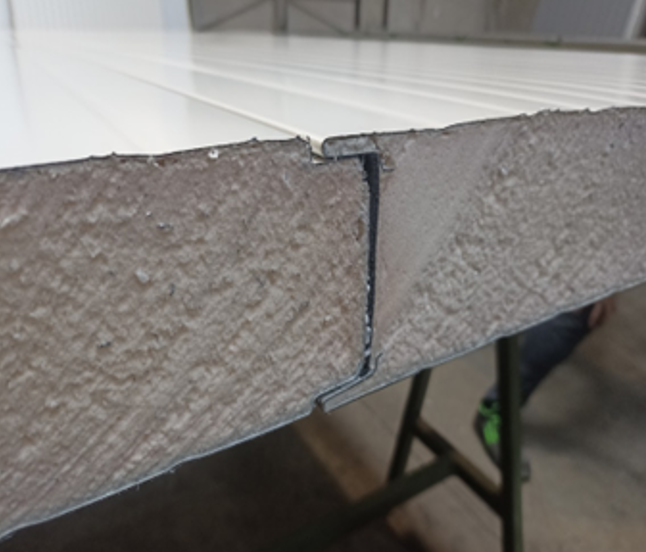

Mean value of maximum load obtained in the test of shear resistance of the connection is 1.56 kN. The tests were carried out on the connection of the sandwich panel and aluminum sub-structure of the thickness of 4mm. The only observed failure mode during the tests of shear resistance of the connection was hole elongation of sandwich panel.

The average value of thermal conductivity of 50 mm thick samples, consisting of PU foam and metal linings, before aging at the reference temperature of +10oC was 0.036 W/(mK). During aging, the samples underwent significant and uneven deformations, which made it impossible to re-test their thermal conductivity and determine their durability.

It was assumed that the metal profiles of the panels do not fit tightly together, and water vapour may penetrate to thermal insulation or expansion tape filling the gap. However, no interstitial condensation will occur. The temperature distribution was calculated as a 2D task. As a result of the analysis, it was found that for typical moderate level of relative air humidity, condensation of water vapor will not occur.

The value of additional heat losses, in form of linear thermal transmittance Ψ, caused by the presence of panel joints is for ISOPAR ELEGANT panels equal to 0.015 W/(mK). It must be considered in the standard calculations of heat transfer.

Relationships between load and elongation

Temperature distribution

Conclusion

The only observed failure mode in the tests of shear resistance of the connection was hole elongation of sandwich panel. Mean value of maximum load obtained in the test of shear resistance of the connection is 1.56 kN. The average thermal conductivity of the Indresmat panels after the production stage, equal to 0.036 W(/mK), is high as for polyurethane insulation and corresponds to the properties of standard insulation made of expanded polystyrene or mineral wool. This can be attributed to the manual preparation of samples since 0,022 W/(mK) was the value achieved in the industrial process for continuous manufacturing. As a result of aging, significant geometric deformations of the tested samples have been observed, which made repeated thermal conductivity tests impossible.

The joint of the sandwich panels does not pose any thermal or moisture problems, and there is no surface or interstitial water vapour condensation risk. The presence of the panels’ joint is associated with the formation of a low intensity thermal bridge and low additional heat losses.

CONSTRUCTION SEGMENT

TEST CATEGORY

Mechanical and Durability

DATE

30 July, 2023