Assessment of an external skin façade photovoltaic integrated construction system

- Home

- Success Stories

- Assessment of an external skin façade photovoltaic integrated construction system

Tejido Flexbrick ® is an industrialized system for flexible ceramic sheets for the construction of cladding and laminated structures. These ceramic textiles open up an endless range of possibilities for dry-assembly cladding systems in architecture Flexbrick, in its commitment to the environment, is working on the integration of the photovoltaics in the ceramic sheets.

PM&VL1 has set-up a dedicated test chain for a comprehensive Building Integrated Photovoltaic (PV), Solar Thermal (T) and hybrid Photovoltaic/Thermal (PV/T) façade systems characterization, facing both Efficiency and Safety requirements. This PM&VL is managed by TECNALIA, the leading private and independent research and technology organization in Spain, with the goal of transforming knowledge into GDP.

Main author:

Joseba Ormaetxea

Tecnalia

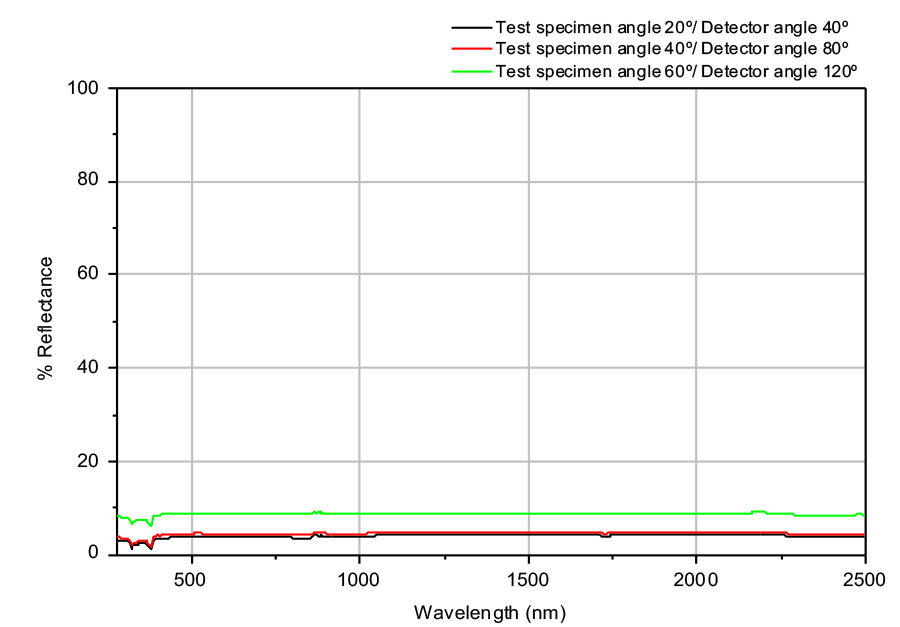

1- Optical tests (280-2500 nm normal hemispherical reflectance and directional reflectance for different angles for incidence of radiation and sample)

2- Static Wind test according to EAD 090062-01-0404

3- Impact test according to EAD 090062-01-0404

4- Reaction to fire (according to EN 13823 –SBI- and EN ISO 11925 -ignitability)

5- Mechanical stresses and environmental actions ageing sequence (new sequence based on IEC 63092:2020, IEC 61215 and IEC TS 63209-1)

Indoor tests of HeliaFilm modules

Image of HeliaFilm thermal Characterization

Main results/outcomes of each test/assessment procedure are shown below:

1. Optical tests

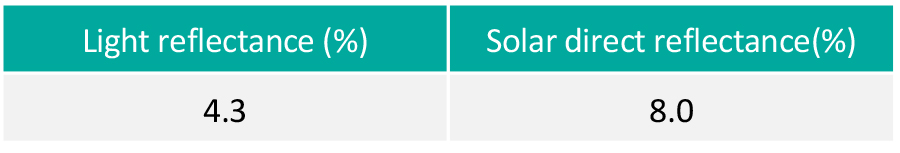

Normal hemispherical reflectance results

2. Static wind test

The module withstood a static load stress of 2,400 Pa. Another additional test was performed to check electrical performance of PV modules. It was concluded that they did not suffer any anomaly, as voltage was measured at similar values before, during and after the test.

3. Impact test results

Impact use category III was obtained.

4. Reaction to fire

B-s1,d0 classification was obtained.

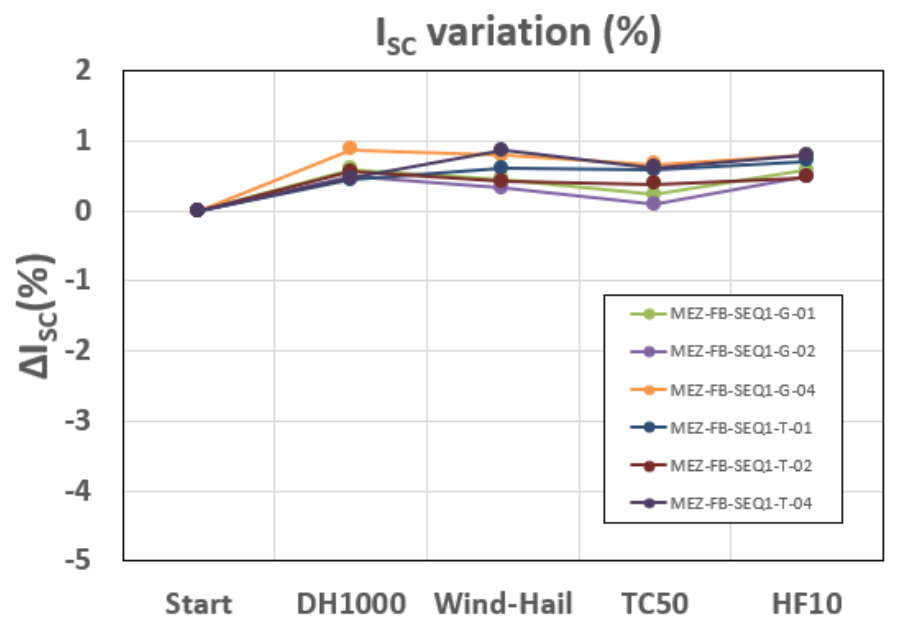

5. Mechanical stresses and environmental actions test sequence

- The samples showed no degradation in terms of short-circuit current after all tests. The modules passed all the insulation tests too. Variations in fill-factor and maximum power were observed due to degradation of the connection to the solar simulator (probably avoided by use of standard connectors upon installation). - The Flexbrick samples withstood the dynamic wind test with no incidence. Besides, the modules were able to withstand hail impacts of up to 2J.

EL before (left) and after (right) the full sequence, with no change

TAMS results

Spectral reflectance at different test specimen angles and detector angles reference

Isc variation during mechanical stresses and environmental actions test sequence

Tejido Flexbrick BIPV modules have endured all performed tests, exhibiting resistance to fire, wind, impacts, and a combination of environmental and mechanical stresses.

Regarding the performed assessment methods:

- The new tests provide significant information about the endurance of the BIPV products against different stressors.

- A new mechanical and environmental actions sequence has been tested showing the reliability of the product against a demanding combination of stresses.

Indoor and Outdoor Performance

06 October, 2025