Durability of membranes and tapes connections to UV and heat

- Home

- Success Stories

- Durability of membranes and tapes connections to UV and heat

Product test:

RC1: TRASPIR EVO 160 and SMART BAND

RC2: TRASPIR EVO UV 115 and FLEXI BAND UV

Mechanical, durability, vibroacoustic, thermal, and microclimate comfort tests of envelope products and their connectors. Mechanical, vibroacoustic, thermal, and structural (scanning and optical microscope, spectrofotometr) tests are used for ageing diagnosis.

Main author:

Aneta Nowak-Michta

Cracow University of Technology

STAGE 1

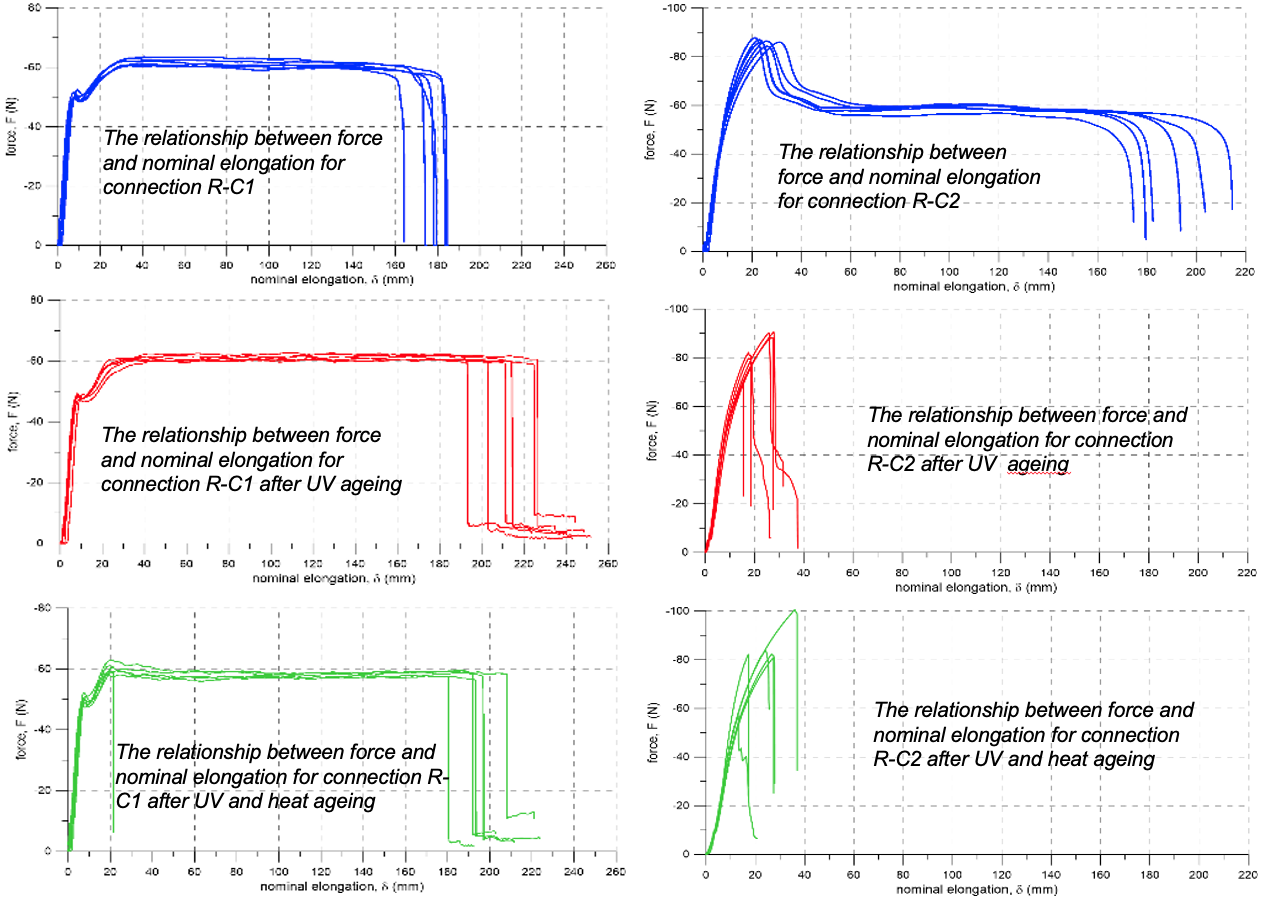

Shear resistance of joints end lap jointing test before ageing according to EN 12317-2

STAGE 2

UV ageing according to Annex C EN 13859-1 with modification to 5000 h

STAGE 3

Heat ageing according to Annex C EN 13859-1

STAGE 4

Shear resistance of joints end lap jointing test after ageing according to EN 12317-2

In order to determine the durability of the connections between membrane and tapes and enhance the credibility of product performance information, a non-standard test was carried out involving the ageing of the connected materials. Moreover, a significantly modified UV ageing time was used from 336 to 5000 hours.

The UV ageing did not influence shear resistance of the joint for the connection RC-1, whereas it caused a slight reduction in shear resistance for the connection RC-2. The UV and heat ageing reduced slightly shear resistance of the joint for both the tested connections. The both used ageing procedures caused the change in the observed failure mode. All the reference specimens failed due to membrane-tape separation. The aged connections RC-1 failed due to membrane peeling. The aged connections RC-2 failed due to breaking of the tape.