New extended-stress sequential testing assessment of a building integrated photovoltaic construction system

- Home

- Success Stories

- New extended-stress sequential testing assessment of a building integrated photovoltaic construction system

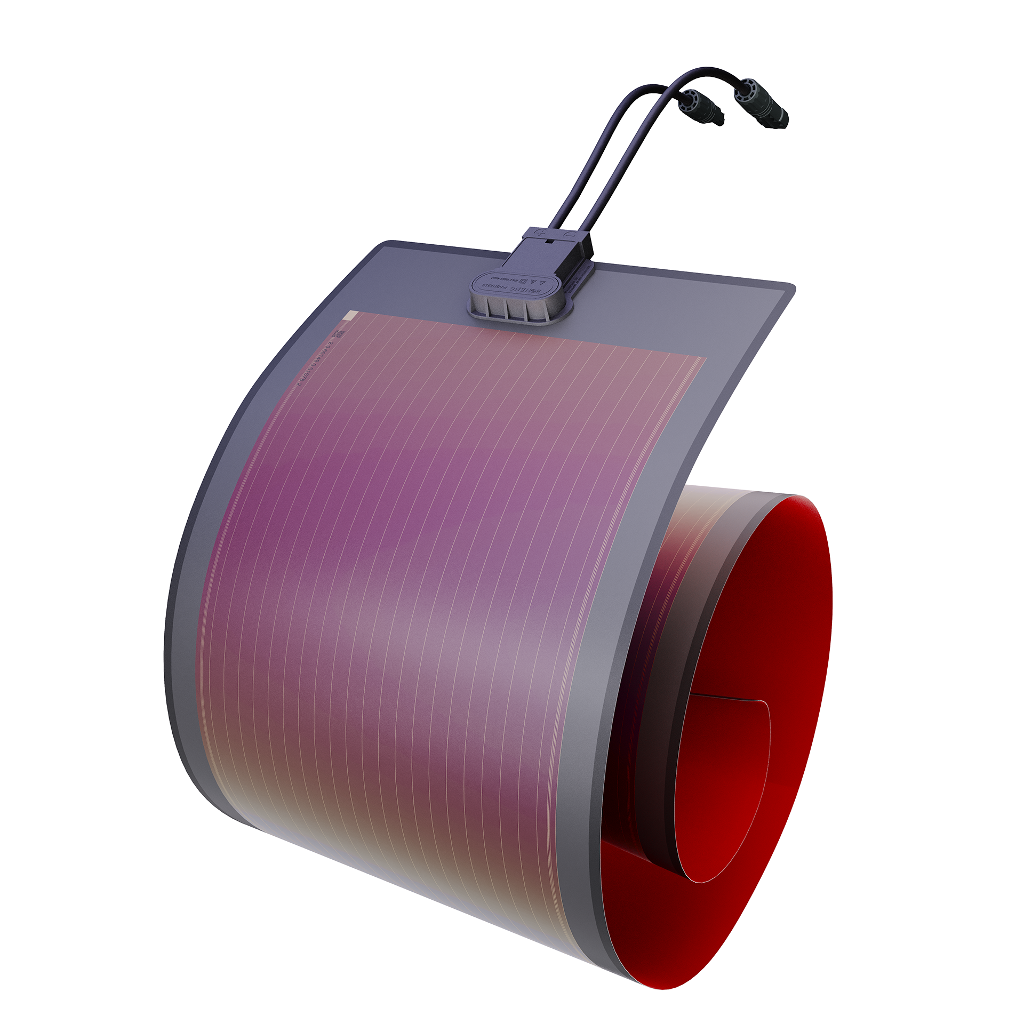

As the technology leader in organic photovoltaics, Heliatek develops, produces and distributes industrial-grade organic PV solar solutions for virtually any building surface (horizontal, vertical, curved, rigid, and flexible). Heliatek stands for energy solutions designed for various traditional and never been possible before applications based on its unique features – it is ultralight, flexible, ultra-thin and truly green. As a R&D activity, they hereby propose the integration of Heliafilm in a dual-glass laminate.

PM&VL1 has set-up a dedicated test chain for a comprehensive Building Integrated Photovoltaic (PV), Solar Thermal (T) and hybrid Photovoltaic/Thermal (PV/T) façade systems characterization, facing both Efficiency and Safety requirements. This PM&VL is managed by TECNALIA, the leading private and independent research and technology organization in Spain, with the goal of transforming knowledge into GDP.

Main author:

Joseba Ormaetxea

Tecnalia

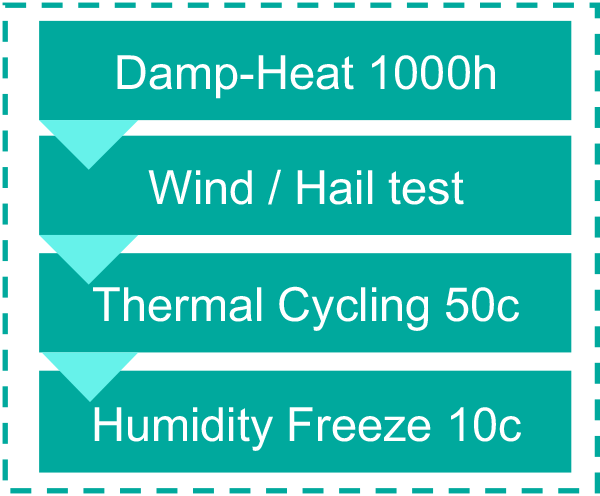

New extended-stress test sequences for BIPV have been performed:

1- New mechanical stresses and environmental actions sequence, based on IEC 63092:2020, IEC 61215 and IEC TS 63209-1, including: damp-heat, hail impact and dynamic wind, thermal cycling and humidity freeze tests

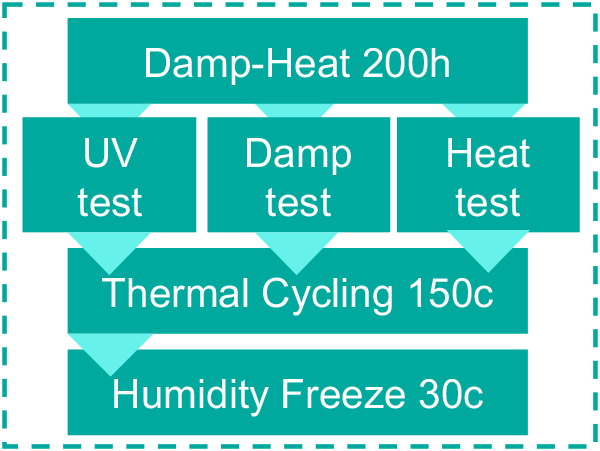

2- Thermal stresses sequence (IEC TS 63209-1) with intermediate characterizations. New UV ageing sequence, based on IEC TS 63209-1 and ISO 12543-4, including extended UV, humidity and high temperature test, as well as damp-heat, thermal cycling and humidity freeze test.

Set-up of the dynamic wind load test

Set-up of the dynamic wind load test

Main results/outcomes of each test sequence procedures are shown below:

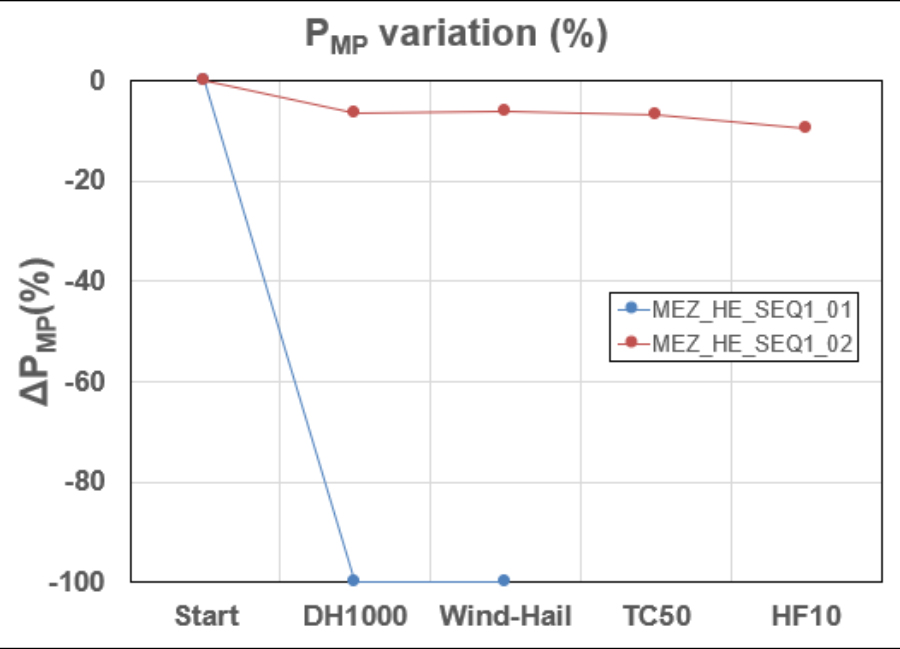

1- New mechanical stresses and environmental actions sequence:

The modules withstood the dynamic wind test, and hail impacts up to 20.7 J, without any harm. The biggest perturbance was observed in damp-heat, caused by humidity ingression in the encapsulate (the current updated polymeric barrier of Heliafilm should solve the problem). The sample had little degradation in thermal cycling and humidity freeze tests, with a cumulative power loss of 9.6 % through the full sequence. It passed all the insulation tests too.

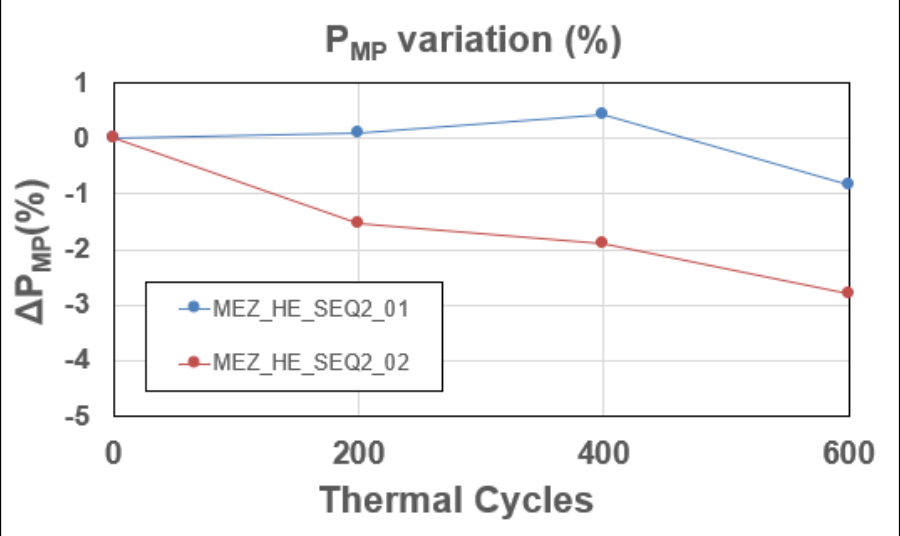

2- Thermal stresses sequence:

The modules went through the extended 600 thermal cycle sequence with no disturbances and passed all the insulation tests.

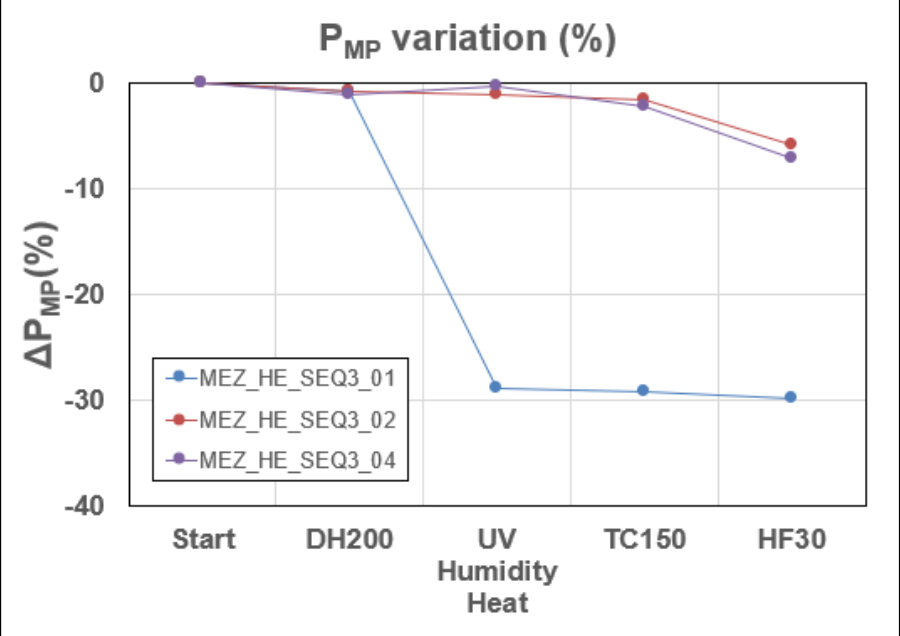

3- New UV ageing sequence:

The samples went through the 200-hour damp-heat test with no perturbation. The extended UV irradiation was the most exigent subsequence path, whereas the humidity and high temperature tests caused no major degradation of the samples. The power loss in the thermal cycling and humidity freeze test was small, with a cumulative efficiency loss of 6-7 % in the samples of two subsequences.

The experimental Heliafilm dual-glass product have endured very hard test sequences. It passed the extended thermal cycling sequence with no major degradation, and most individual tests with minor power losses.

The module shows more susceptibility to hard UV and extended damp-heat exposure. The latter will be tackled by the new polymeric layer of the product.

Regarding the new performed assessment sequences, they provide significant information about the endurance of the BIPV products against demanding combinations of various stresses representative for integration in building façades.

Mechanical, Thermal and UV ageing

06 October, 2025