Assessment of formaldehyde removal by photocatalytic coating

- Home

- Success Stories

- Assessment of formaldehyde removal by photocatalytic coating

Product: Photocatalytic coating

Tecnan produces different kinds of active nanoparticles, and its catalogue includes several ranges of products such as hydro and oleo repellent coatings, specific water repellent products, anti-soiling self-cleaning products and easy-to-clean as well as protective coatings. This specific formulation contains photoactive nanoparticles that, when irradiated, are able to degrade formaldehyde molecules present in the indoor atmosphere.

The scope of the PM&VL2 is a complete characterization of all the envelope parts and their effects on internal occupants in real operating conditions. The VOC (Volatile Organic Compounds) Lab node offers a characterization of the VOC emissions of building materials under standard or customized environmental conditions.

Main author:

Chiara Nomellini

EURAC Research

The test procedure employed is based on the ISO 18560-1:2014 standard with several modifications:

- the light source was positioned inside the test chamber,

- an adequate amount of formaldehyde was injected to achieve the desired target concentration,

- a dedicated formaldehyde analyser for measuring the concentration of formaldehyde in continuum was employed.

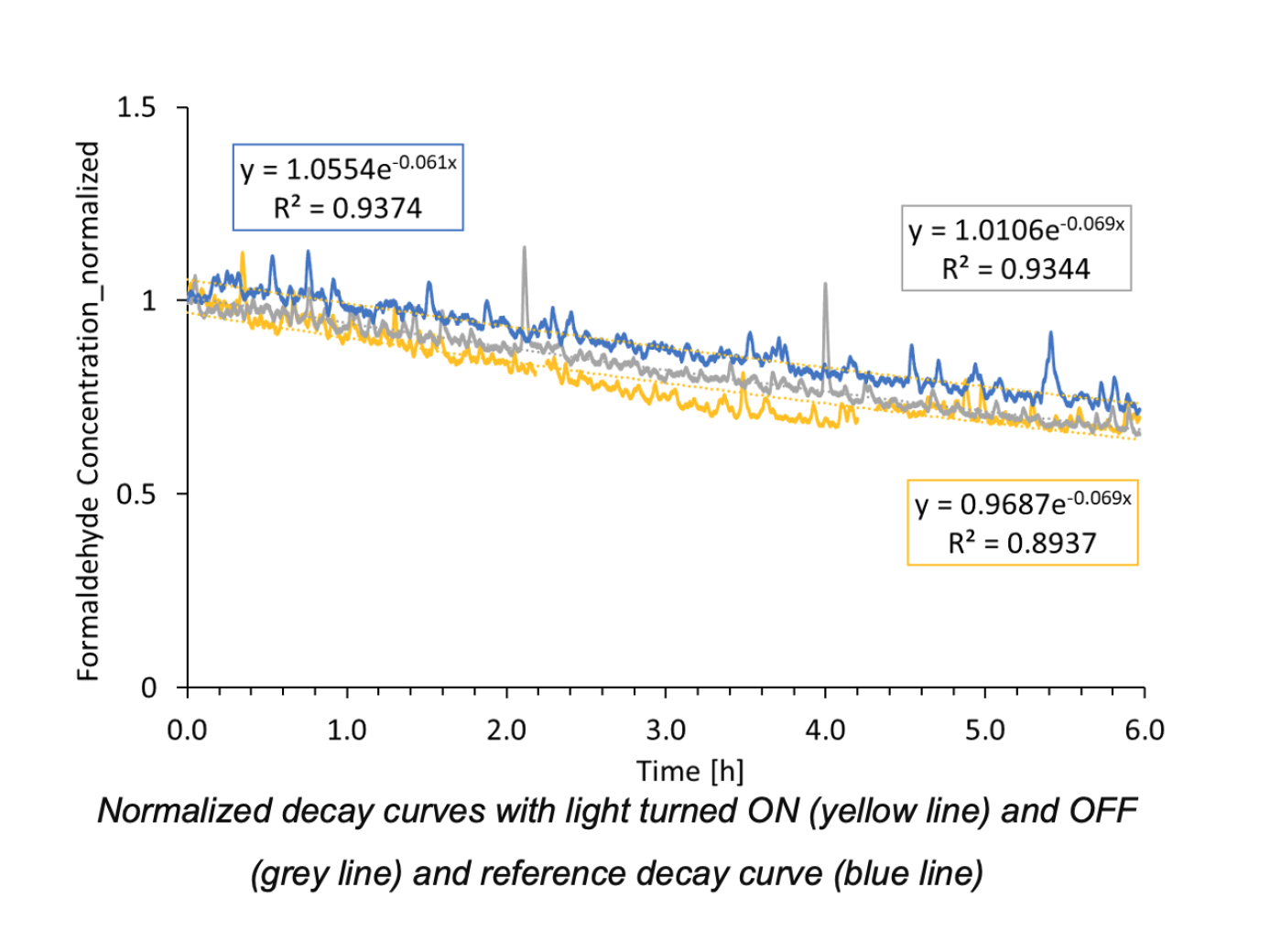

In order to determine the performance for formaldehyde removal by the photocatalytic coating the reference decay curve of formaldehyde concentration in the chamber is obtained and it is later compared with the decay curve obtained in the presence of the test specimens and with the light source turned on.

Test specimens in the test chamber with the experimental set-up

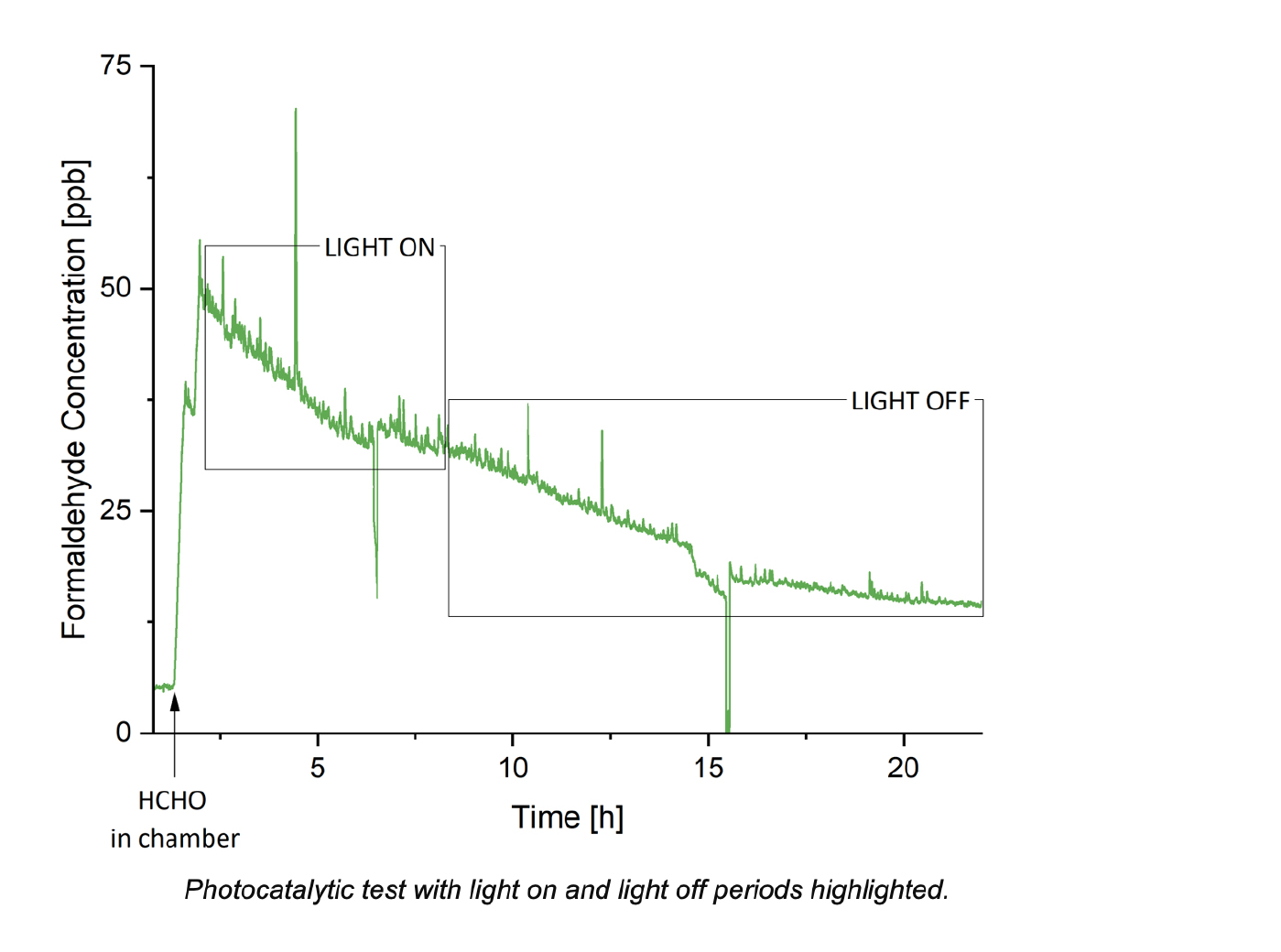

The formaldehyde concentration in the test chamber was monitored for more than 20 hours, of which 6 hours consisted in the photocatalytic HCHO decay test performed with the artificial illumination source turned on.

In order to assess whether the coating applied to the test specimens was actively degrading the formaldehyde present in the test chamber, a fitting curve was calculated for the HCHO decay both in presence and absence of light, and both were then compared with the previously obtained reference decay curve.

The same decay rate constant was obtained both under illumination and in dark conditions (0.069), a value that resulted to be however higher than the constant obtained by normalizing the reference decay curve (0.61).

This indicates that, with respect to the reference curve, the decay of formaldehyde during the photocatalytic test resulted to be faster, but no sensible difference in this degradation rate was detected between the curves recorded in presence and absence of irradiation

The analysis of the results, in particular the calculation of the decay rate constants in dark and under illumination, did not yield results consistent with an accelerated formaldehyde degradation when the test specimens were irradiated with a light source. The photocatalytic properties of the tested coating could be further characterized by varying some experimental conditions, such as the illumination source and by increasing the surface/volume ratio by increasing the area coated with the photocatalytic product.