MEASUREMENT & VERIFICATION (PM&VL 7)

Product test:

Membrane TRASPIR EVO UV 115

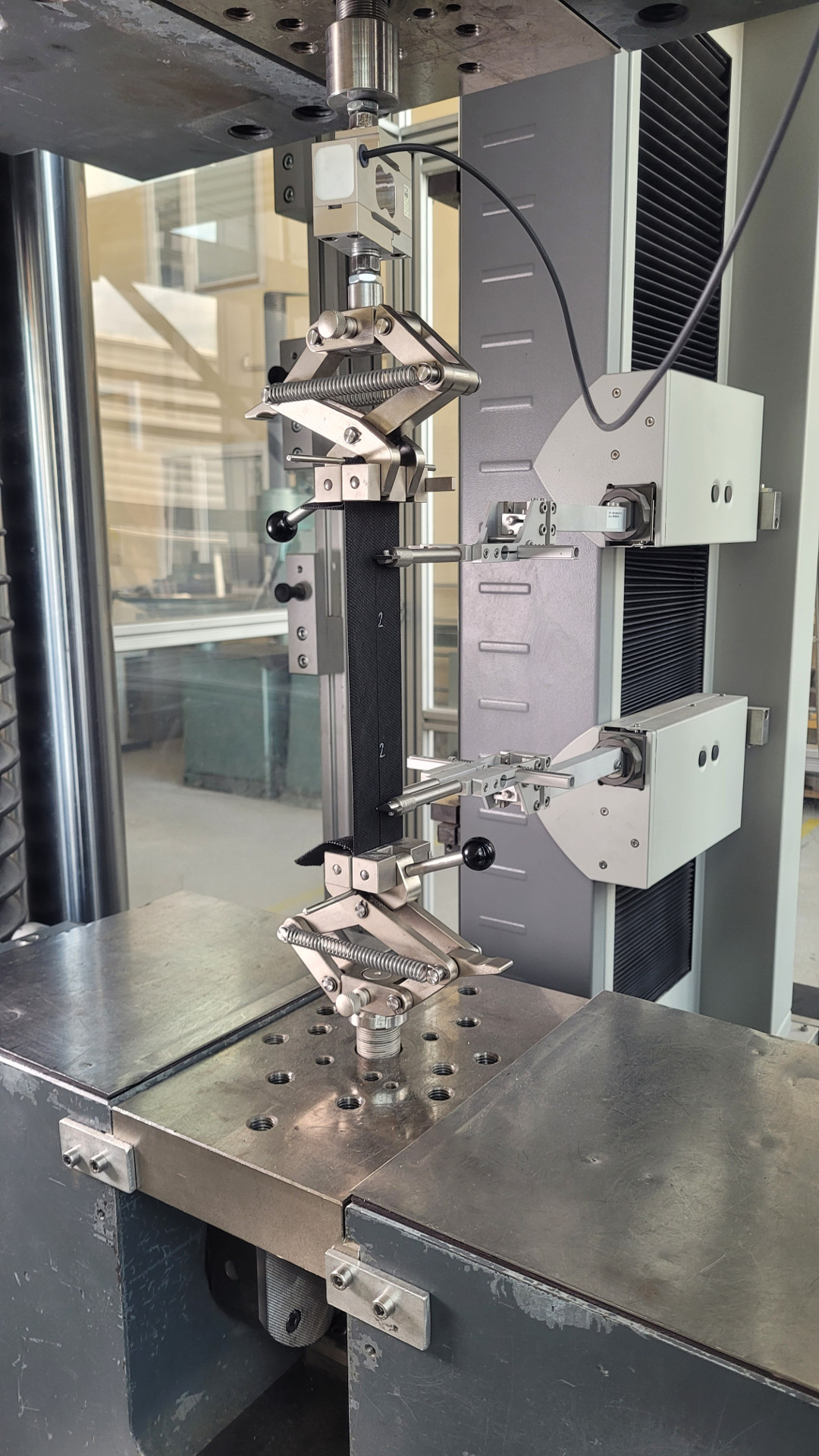

Mechanical, durability, vibroacoustic, thermal, and microclimate comfort tests of envelope products and their connectors. Mechanical, vibroacoustic, thermal, and structural (scanning and optical microscope, spectrometer) tests are used for ageing diagnosis.

ABOUT

Safety

Efficiency

PARTNERS

Scientific partner

Cracow University of Technology

Industrial Partner

Rothoblaas

Main author:

Aneta Nowak-Michta

Cracow University of Technology

The implemented program of mechanical and durability tests was based on certification requirements for membranes with appropriate modifications taking into account more intense UV exposure than those provided for in the standard. The obtained results set the path for further research and product development as well as making the construction products comparable.

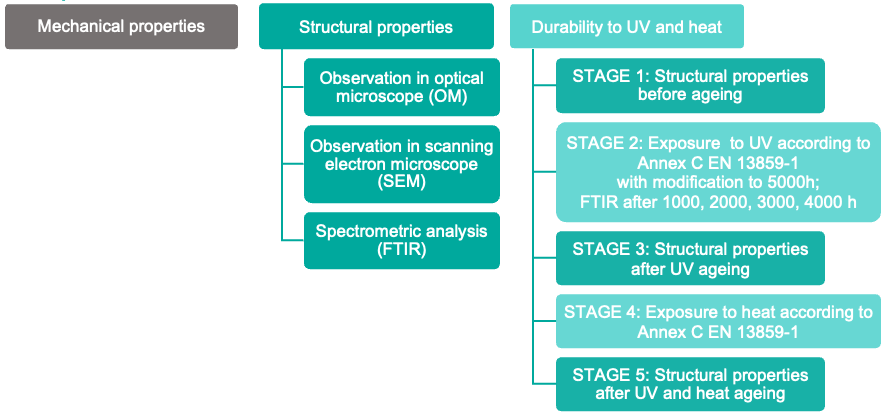

Design of Experiments

Results

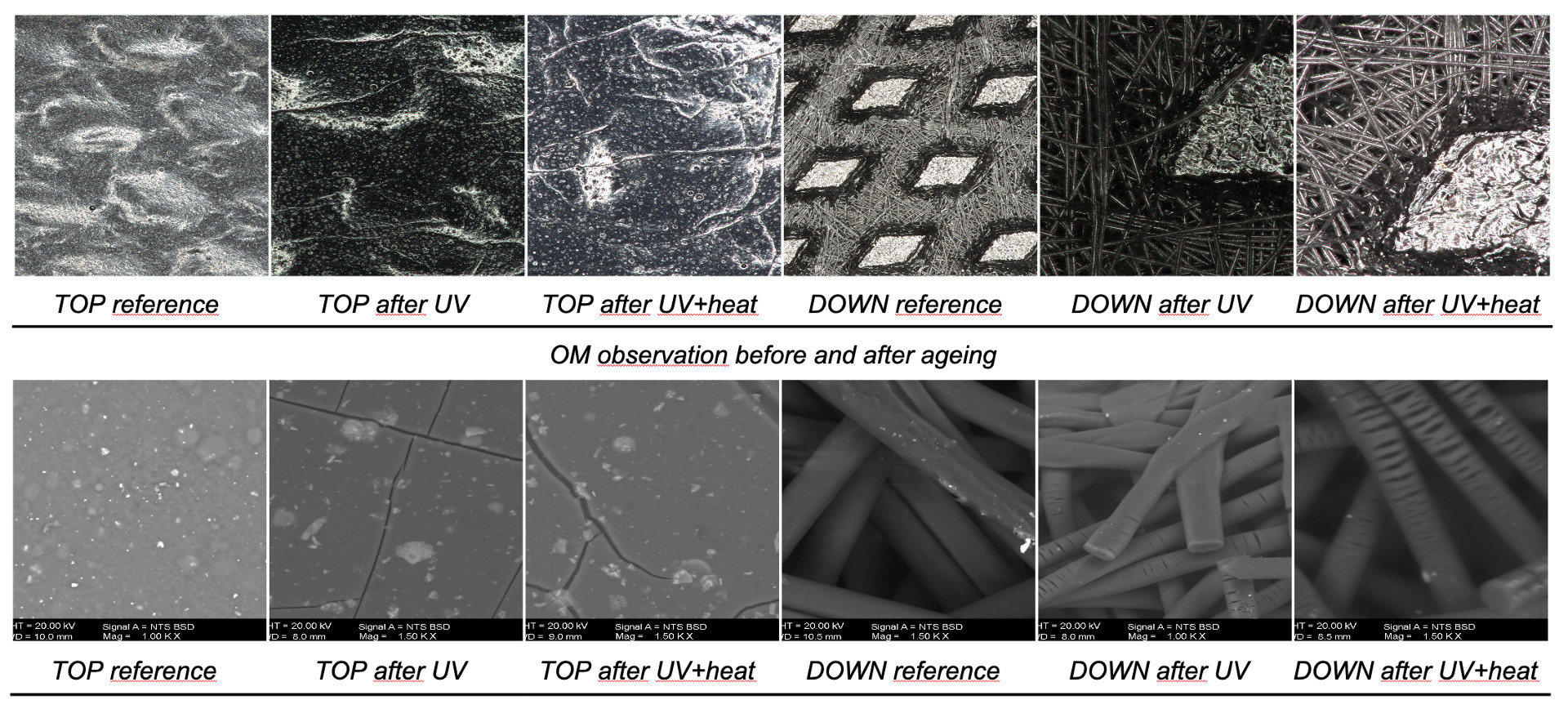

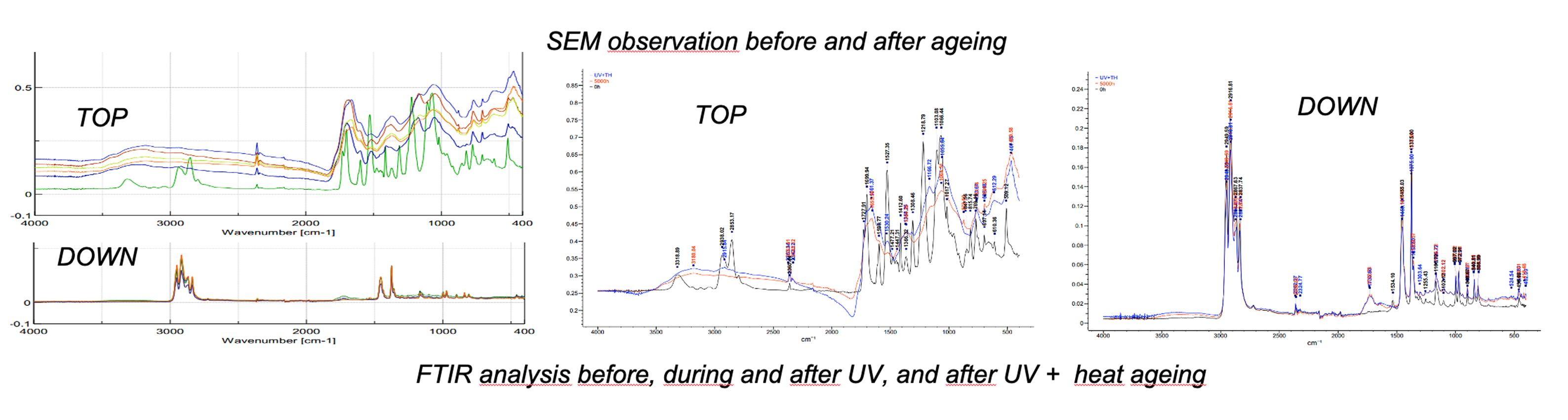

The standard ageing time under UV rays was significantly modified from 336 to 5000 hours to better reflect real exposure conditions and enhance the credibility of product performance information. In addition, the scope of diagnostics before and after ageing was extended to include the observation of microstructure in an optical and scanning microscope as well as FTIR analyses before, during and after ageing.

Conclusion

Exposure to 5000h UV of membrane causes their degradation (the both side) visible changes include microcracks and defragmentation of fibers PP. IR spectra after exposure to UV for 1000, 2000 3000, 4000 and 5000 hours allow to monitor changes and determine the beginning of degradation. IR spectra and SEM images show that exposure to heat intensifies the degradation process. No additional changes were observed.